Nitriding is a popular case hardening technique renowned for the qualities it delivers at relatively low process temperatures.

Salt bath nitriding —also known as ferritic nitrocarburizing (FNC)— is one of the most popular ways to achieve these results, but it isn’t the only way. In fact, nor is it the safer way.

How salt bath nitriding works

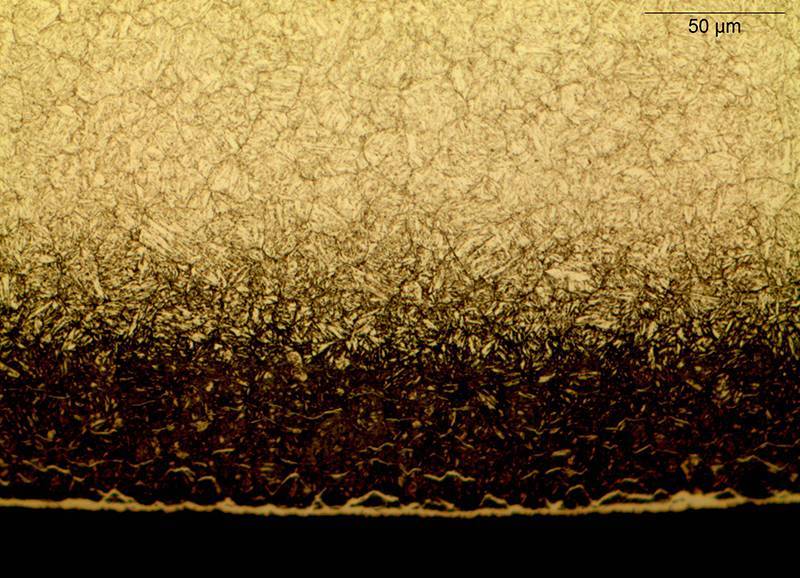

The hallmark of salt bath nitriding is the bath of molten salt (usually cyanide or other salts) into which parts are submerged. The method features the transfer via diffusion of carbon and nitrogen from the molten salt to the surface of a steel part. It remains a popular case hardening technique because it offers:

- Increased hardness and wear resistance at part surfaces while cores remain softer and more ductile.

- Increased corrosion resistance.

- Significantly reduced risk of distortion due to a comparatively lower treatment temperature.

An advantage of the salt bath nitriding process is that it’s carried out at lower temperatures that keep parts in the ferritic phase, leading to reduced risk of distortion during treatment.

The popularity of salt bath nitriding is largely due to heat treaters’ successful marketing of trademarked FNC processes based on the salt bath method. The ubiquity of these trademarked nitriding processes often leaves engineers unaware or skeptical that the same metallurgical properties can be achieved via ferritic nitrocarburizing in a furnace.

Problems with salt bath nitriding

As we’ve alluded, salt bath nitriding can lead to some problems in terms of both safety and cost:

- Caustic cyanide solutions put operators at risk of serious injury if molten salt contacts their skin.

- Parts with unsealed seams or complex geometries can trap the salt solution even after rigorous rinsing. That puts workers at risk for additional caustic exposure if the salt shakes loose later and can increase the risk of corrosion damage to parts.

- Molten salt baths cannot be turned off. The salt must remain molten, so baths must stay heated even when they’re not in use.

Safety and economy with gas FNC

One of the constants in metallurgy is the ability to achieve the same results through different processes. Such is the case when comparing parts case hardened in salt baths versus those hardened in FNC furnaces.

Gas FNC delivers minimized distortion risk, corrosion resistance and higher hardness at the surface and retained core ductility just as well as the salt bath nitriding process does. But gas FNC comes with fewer hazards and headaches. There are no caustic chemicals involved, no post-treatment cleaning is required and gas furnaces —unlike salt pots— can be turned off when they’re not in use.

At Paulo, we mostly use ammonia in conjunction with other carbon-containing gases to supply nitrogen and carbon to steel parts. In addition, our gas furnaces feature digital process controls that let us fine-tune treatments to exact temperatures and gas concentrations. It allows us to meet even the most precise and unique specifications.

Paulo leads the way

We’re pushing our gas FNC capabilities to new heights. Planned equipment upgrades include a massive gas FNC furnace in our St. Louis Division and a new, low-pressure nitrider with improved digital process controls in our Nashville Division. In addition, more FNC capacity will become available once construction on our newest division in Monterrey, Mexico is complete.

Our goal at Paulo is to be more like a department within our customers’ own facilities. That means we approach our work with superior performance, economy and risk management in mind. Striking that balance requires the leading expertise that comes with 75 years in business.

If you have any questions or want to discuss nitriding methodology with a metallurgist, contact us. Our experts are happy to help. Find more information on risk management in heat treatment by downloading our guide.