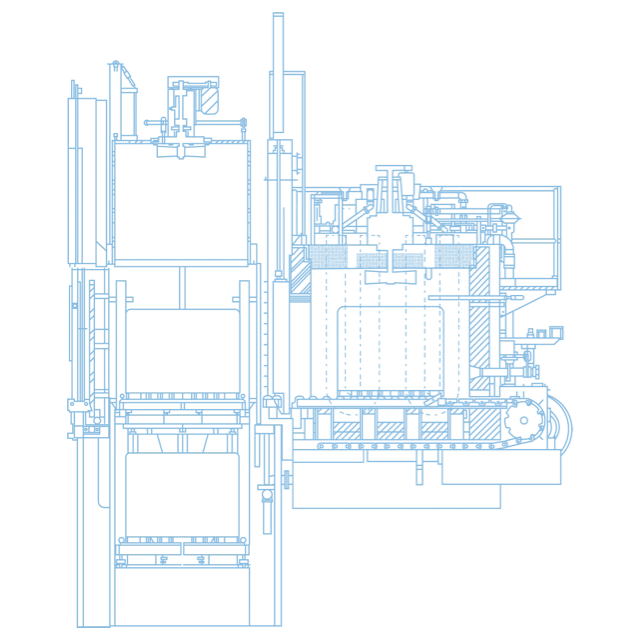

Integral Quench Furnaces

Integral quench (or batch) furnaces often prove ideal for small batches of parts, larger-sized parts and parts which require some flexibility in cycle time.

Controlled atmosphere for consistent results.

As opposed to a continuous heat treating furnace, our integral quench furnaces feature enclosed, atmosphere-tight heating chambers, not unlike a heavy-duty version of the oven found in your home kitchen. This allows us to keep parts within a protective, controlled atmosphere throughout the heat treatment. Unlike your home kitchen, however, Paulo’s integral quench furnaces reach 1750 degrees Fahrenheit and run four processes for the treatment of metal parts: neutral hardening, carburizing, carbonitriding and ferritic nitrocarburizing.

Automated system

We have invested in a high-tech, computer controlled system for fast, consistent results.

Flexibility

Our furnaces can accommodate a variety of sizes and weights and run cycles as long and complex as a project demands.

Consistent processing

Our integral quench furnaces provide uniform temperatures in a controlled atmosphere throughout processing.

The Right Process for Your Parts.

Because batch furnaces operate with enclosed heating chambers, a part’s size will factor into deciding whether or not this equipment is right for your job. Paulo’s integral quench furnaces range up to 36 inches by 48 inches by 36 inches to fit a variety of small to midsized parts. Larger, heavier components can also be processed in these furnaces if long heat treat times are required.

From initial customer specifications to production management to quality control, we utilize one of the most sophisticated purpose-built computerized control systems in the industry, the Paulo Universal Batch System (PUBS), to help ensure that conditions within our integral quench furnaces match the time, temperature and atmospheric conditions required for every project.

Start a conversation.

We’re ready to provide you with the best options for your next neutral hardening, carburizing, carbonitriding and ferritic nitrocarburizing project. Request a quote or contact us today learn more about our equipment and approach.

GET A QUOTE