Some big questions have been banging around the boardrooms and corner offices of aerospace OEMs worldwide for a couple years:

How do we overcome a global backlog of orders?

What tweaks can we make at key supply chain stages to get things moving faster?

How can we help suppliers ramp up production while maintaining quality?

Indeed, the pressure’s on for suppliers who make up the industry’s complicated global supply chains.

At the heart of that challenge is an opportunity—one we think is worth seizing. Aerospace OEMs need a boost. Serious long-term growth awaits the suppliers who can give it to them.

To meet the challenges plaguing the industry, OEMs have lately taken matters into their own hands. For instance, both Boeing and Airbus have recently gone vertical, using joint ventures or outright takeovers to stave off risk and uncertainty.

Vertical integration has been the industry’s recent reflex, but only when it makes business sense. OEMs can’t acquire their way out of the pinch. The door is open for other industry players to step up by increasing production capacity to work through the backlog, continuously improving efficiencies in the face of growing price pressures and remaining committed to the research and development efforts that push the industry forward.

We know that our specialty—thermal processing and metal finishing—is but one piece of a huge puzzle. But we’ve been around long enough to know a chance to make a meaningful difference when we see it.

We try to see what the industry sees on the horizon and react accordingly. It’s produced tangible results we know will deepen our ties to aerospace customers. The most notable is a multi-phase expansion at our Cleveland Division, a location specializing in aerospace thermal processing.

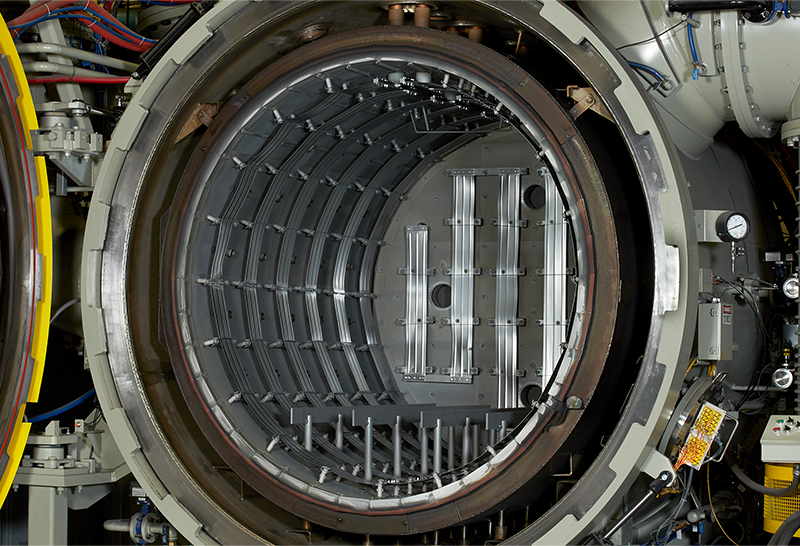

Phase one of an ambitious expansion at the site is underway: A 30,000-square-foot addition to the existing plant is under construction as we speak. A new vacuum furnace—the first of an order of five—was installed there in July. When the expansion is complete, we’ll have added 50,000 square feet to the site.

This increase in our capacity to execute advanced thermal processes is mutually beneficial: For us, it’s good for business. But it also alleviates some of the pressure on the upper-tier aerospace suppliers who outsource heat treating.

Adding service offerings can be just as crucial as expanding current ones. As aerospace components become more and more complex, the thermal processes required for them to perform as designed must also evolve. We added hot isostatic pressing (HIP) capabilities to our menu of aerospace heat treating services to meet that need. As a result, we’re in position to work directly with OEMs to develop the industry’s next generation of advanced thermal processes.

But it doesn’t stop there. Investing in increased capacity and new equipment is accompanied by our continuous efforts to secure key industry certifications and approvals. For instance, two of our plants (Cleveland and Kansas City) meet aerospace-specific Nadcap and AS9100 requirements.

All these elements come together in our promise to customers: We’ll continue to develop advanced processes that meet the industry’s rigorous demands. And with our industry-leading quality systems, we’ll guarantee consistency and quality for the duration of a relationship.

Expanding our facilities and filling them with equipment is expensive. Adding new service offerings can be costly and sometimes risky. Achieving and maintaining certifications is rigorous work. But it’s well worth the investment: Existing relationships are strengthened. New partnerships are formed. Aircraft fly safely in the sky. And the industry is the better for it.

Want to dig deeper? Read our Comprehensive guide to advanced aerospace thermal processing.